Oil Free Compressor For Oxygen Generator ZW-140/2-A

Product Introduction

| Product Introduction |

| ①. Basic parameters and performance indicators |

| 1. Rated voltage/frequency:AC 220V/50Hz |

| 2. Rated current:3.8A |

| 3. Rated power:820W |

| 4. Motor stage:4P |

| 5. Rated speed:1400RPM |

| 6. Rated flow:140L/min |

| 7. Rated pressure:0.2MPa |

| 8. Noise:<59.5dB(A) |

| 9. Operating ambient temperature:5-40℃ |

| 10. weight:11.5KG |

| ②. Electrical performance |

| 1. Motor temperature protection:135℃ |

| 2. Insulation class:class B |

| 3. Insulation resistance:≥50MΩ |

| 4. Electrical strength:1500v/min(No breakdown and flashover) |

| ③. Accessories |

| 1. Lead length : Power-line length 580±20mm, Capacitance-line length 580+20mm |

| 2. capacitance:450V 25µF |

| 3. Elbow:G1/4 |

| 4. Relief valve: release pressure 250KPa±50KPa |

| ④. Test method |

| 1. Low voltage test :AC 187V. Start the compressor for loading, and do not stop before the pressure rises to 0.2MPa |

| 2. Flow test : Under the rated voltage and 0.2MPa pressure, start to work to a stable state, and the flow reaches 140L/min. |

Product Indicators

|

Model |

Rated voltage and frequency |

Rated power(W) |

Rated current(A) |

Rated working pressure (KPa) |

Rated volume flow(LPM) |

capacitance(μF) |

noise(㏈(A)) |

Low pressure start(V) |

Installation dimension(mm) |

Product dimensions(mm) |

weight(KG) |

|

ZW-140/2-A |

AC 220V/50Hz |

820W |

3.8A |

1.4 |

≥140L/min |

25μF |

≤60 |

187V |

218×89 |

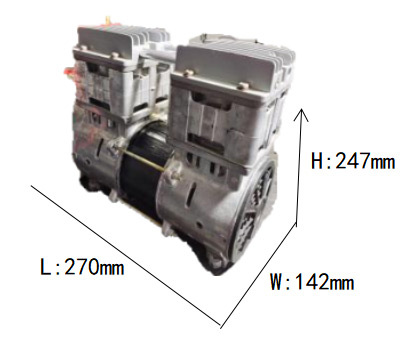

270×142×247 (See the real object) |

11.5 |

Product Appearance Dimensions drawing: (Length: 270mm × Width: 142mm × Height: 247mm)

Oil-free compressor(ZW-140/2-A)for oxygen concentrator

1. Imported bearings and sealing rings for good performance.

2. Less noise, suitable for long-term operation.

3. Applied in many fields.

4. Copper wire motor, long service life.

Compressor common fault analysis

1. Abnormal temperature

Abnormal exhaust temperature means that it is higher than the design value. Theoretically, the factors affecting the increase of exhaust temperature are: intake air temperature, pressure ratio, and compression index (for air compression index K=1.4). Factors that affect the high suction temperature due to actual conditions, such as: low intercooling efficiency, or excessive scale formation in the intercooler affects heat transfer, so the suction temperature of the subsequent stage must be high, and the exhaust temperature will also be high. In addition, gas valve leakage and piston ring leakage not only affect the rise of exhaust gas temperature, but also change the interstage pressure. As long as the pressure ratio is higher than the normal value, the exhaust gas temperature will rise. In addition, for water-cooled machines, lack of water or insufficient water will increase the exhaust temperature.

2. Abnormal pressure

If the air volume discharged by the compressor cannot meet the user’s flow requirements under the rated pressure, the exhaust pressure must be reduced. At this time, you have to change to another machine with the same exhaust pressure and larger displacement. The main reason affecting the abnormal interstage pressure is the air leakage of the air valve or the air leakage after the piston ring is worn, so the reasons should be found and measures should be taken from these aspects.